How many kinds of toilet paper cutting machines in the market?

- Manual toilet paper cutting machine.

- Automatic toilet paper cutting machine

- Double channel log saw paper cutting machine

- Automatic maxi roll/public jumbo roll paper cutting machine

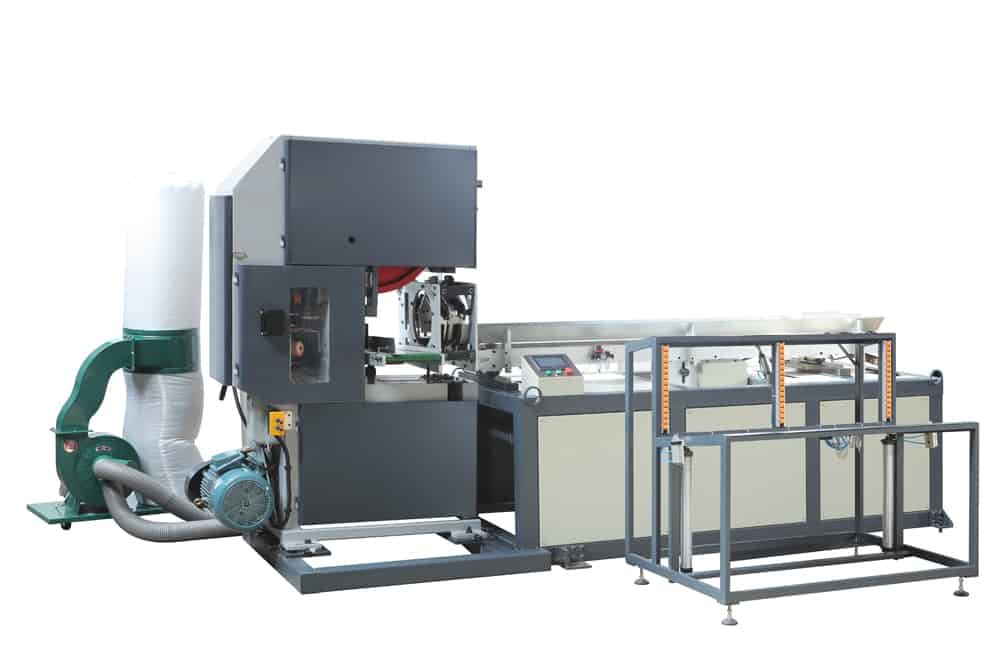

Automatic toilet paper cutting machine

How to select a toilet paper cutting machine?

automatic maxi roll public jumbo roll paper cutting machine

- Depend on your invest amount:

A Double Channel Log Saw Paper Cutting Machine will be much more expensive than a Manual and Automatic Paper Cutting Machine. We can help you design and select the Right Machines according to your budget.

- Depend on your final products:

Different Paper Cutting Machine can cut different paper rolls sizes.Such as Maxi Roll/Public Jumbo Roll Paper Cutting Machine,The range it can cut is:Cutting length: 50~230mm; Core thickness: 1.1mm-6mm;Cutting diameter: 150~300mm.

- Depend on your production capacity:

Double Channel Log Saw Paper Cutting Machine is with High production Capacity and will save the labor cost too. Different Sizes of Machines will also affect Production Capacity.

- Depend on your market demands:

There will have popular sizes of paper in your local market (Toilet Rolls, Kitchen Towels, Public Jumbo Rolls, Maxi Rolls, etc. ) and you can select the Right Machines to meet your market demands.

- Depend on your factory place:

The Manual Toilet Paper Cutting Machine and the Automatic Toilet Paper Cutting Machine is adjust to the small and medium factory.Cause these two machines needs amaller space to work.

In an other side,the Double Channel Log Saw Paper Cutting Machine is adjust to the big producers.Because its high speed and continuity

8 reasons to choose the double channel log saw cutting machine:

Double channel log saw paper cutting machine

- It is completed by processes such as automatic material input, length setting/measurement, cutting, and finished product output;

- It adopts PLC and man-machine interface system operation to flexibly change the sharpening time, cutting speed, and cutting length, and the cutting efficiency is high;

- Adopt frequency converter speed control and servo tracking control, and combine with light, electricity, and gas phase, the screw packaging machine is priced to cut off the length, and the cut surface is flat;

- Adopt safety protection function, safe and reliable operation;

- The single-channel paper cutter can be designed to rotate up and down, and the paper towel cut surface is more flat, especially suitable for paper towels with a height of more than 120mm;

- It has the ability to automatically measure the length of the uncut paper towel, and divide the length of the paper towel according to the setting, avoiding the length deviation caused by the accumulated error of one paper screw vacuum packaging machine towel after each row or after;

- It can be designed according to customer’s requirements, remove the uneven surface of the head and tail, and automatically discharge the waste (especially suitable for soft paper packaging machine packaging);

- It can be automatically produced in line with equipment such as paper machines, automatic box sealing machines, and soft paper packaging machines.

How to maintain toilet paper cutting machine?

Question 1: Why dose the Toilet Paper Cutting machine act, but not turn on the foot switch When the machine is semi-active ?

Reasons :The footswitch of toilet paper cutting machine is damaged or the water in the foot switch or the manual start button switch is broken.

Solution:Replace the new switch, socket, push button switch or disassemble the repair associated damage.

Question 2: When the semi-active operation is performed, the foot switch slide is lowered, and then rolled up and then raised.

Reasons:The proximity switch on the left side of the cross slide is damaged or disconnected.

Solution:Replace the switch or the switch connection.

Question 3: When the semi-active work is performed, the foot slide switch is lowered, and the print stand does not move after being moved to the left.

Reasons:

a. The left side switch of the horizontal slide is not sensed or has doubts.

b. The micro switch in the foot switch does not move.

Solution:

a. Adjust the left side proximity switch sensing point or replace the good proximity switch;

b. Adjust, correct or replace the new microswitch with the microswitch in the footswitch.

Question 4: When the semi-active operation is stepped on the foot switch, the slide seat is lowered to the left and then rises but not moved to the right.

Reasons:There is a problem with the proximity switch on the upper left side of the vertical slide or the proximity switch.

Solution:Adjust the proximity switch or the very close proximity switch.

Question 5: After the action is switched, the rising motion is slow and half beat.

Reasons:The solenoid valve is blocked by a foreign body or the solenoid valve is faulty.

Solution:Remove the solenoid valve to clean or replace the solenoid valve.

Question 6: manual, semi-active all do not move, the power light is on.

Reasons:A low-voltage side fuse blown, no gas source enters, and all the solenoid valves have problems.

Solution:Change the low-voltage side fuse to see if the pressure reaches 4-7kg/cm. The solenoid valve is very small, and most of them are disconnected.